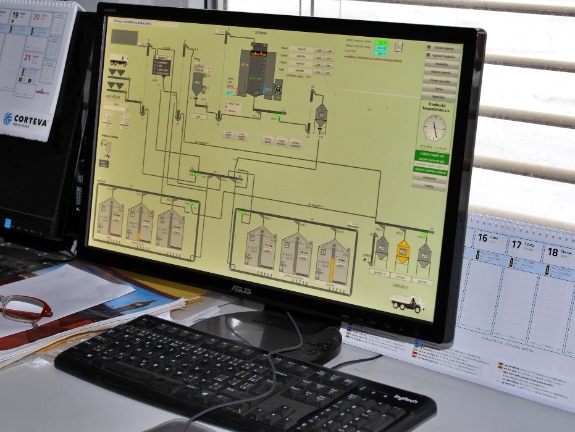

The computer control of the post-harvest line is a state-of-the-art control system, where the operator starts the selected program by clicking the mouse on the control scheme on the PC monitor in the control room. The system is programmed exactly according to the needs and wishes of the investor. All necessary data and statuses are monitored and recorded. The current status of silo filling, grain temperatures inside the silo, outside temperature and humidity are basic data that the operator can see and evaluate directly on the PC monitor. The ventilation triggering system is dependent on the current outside air condition, temperature, humidity and time and its aim is to balance the temperature difference between inside and outside the silo as best as possible to avoid condensation and thus deterioration of the stored grain.

Important statuses can be displayed remotely, e.g. on a mobile device. We also use remote access for immediate service interventions and monitoring of fault conditions to identify potential faults. The control of the entire post-harvest line is implemented via a control panel installed on a personal computer running Windows XP and Control Web 6.1. It can be used to start motors, close or open flaps and gates.

Controlling the machines and starting the paths is very simple and intuitive. For example, if you want to start a certain transport path, you set the flaps and gates to the appropriate positions using the left or right mouse button and click on the machines you want to start with the left mouse button (if you want to turn off a machine, click on it with the right mouse button). Before the first machine in the path is started, the warning horn will automatically sound.

Among other things, the system is set to automatically start the machines associated with the purifier. This means that when the purifier is started, all conveyors and fans associated with the purifier, including the fan on the cyclone, are automatically started.

Starting the lower aeration and upper exhaust fans is done either manually, by clicking on the respective fan, or by a timer. The timer setup panel is displayed by clicking on the "Fan Timing" button. In it, for each silo separately, the clock in which the fan will run in the respective silo can be set. The running of the fans is blocked by the outside temperature and humidity, the values are set in this panel.

Level gauges are installed in the main silos and in the storage silo for the dryer. These show the free space in meters with a resolution of 0.1 m. Maximum level sensors are installed in the dispatch hoppers. When the sensor switches on, the fill light on the screen illuminates, the horn sounds and a message window is displayed. At the same time, the first conveyor of the path to the silo stops.

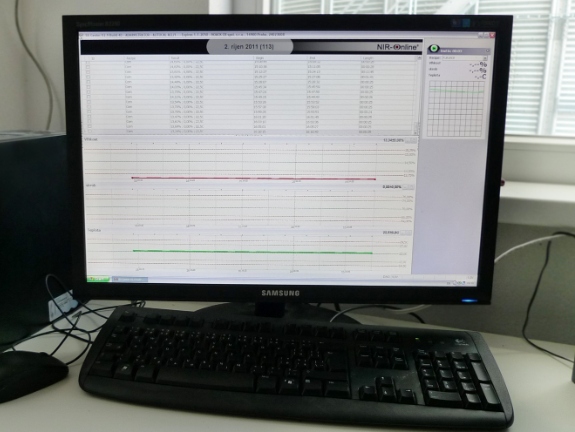

In the main silos, thermometer cables are installed, the number of which is derived from the diameter of the silo. Measurements are taken continuously (if the computer is switched on). In the temperature measurement panel, it is possible to set a threshold from which the temperature reading turns red. This indication depends on the level in the silo (only temperatures in the crop are taken into account, not in the empty space above), and the setting is separate for each silo. Each day the measured temperatures are recorded in the archive. Each silo has its own archive, which is broken down by calendar month, with an archiving period of one year. The archived temperatures can be displayed and printed as a table or displayed as a color graph.

Zpráva z veletrhu AGRITECHNICA 2025

V německém Hannoveru právě vrcholí mezinárodní zemědělský veletrh AGRITECHNICA 2025, největší světová...

Zpráva z veletrhu AGRITECHNICA 2025

V německém Hannoveru právě vrcholí mezinárodní zemědělský veletrh AGRITECHNICA 2025, největší světová...

PAWLICA na veletrhu AGRITECHNICA 2025!

Podívejte se na naši prezentaci z Hannoveru a objevte novinky v oblasti skladování, manipulace a...

PAWLICA na veletrhu AGRITECHNICA 2025!

Podívejte se na naši prezentaci z Hannoveru a objevte novinky v oblasti skladování, manipulace a...

PAWLICA & AGE na AGRITECHNICA 2025 v Hannoveru!

Navštivte nás 9.–15. listopadu 2025 na největším světovém veletrhu zemědělských technologií.

...

PAWLICA & AGE na AGRITECHNICA 2025 v Hannoveru!

Navštivte nás 9.–15. listopadu 2025 na největším světovém veletrhu zemědělských technologií.

...

Reportáž z Dlouhé Vsi je online!

26. září jsme společně slavnostně otevřeli novou posklizňovou linku ZEA Rychnovsko a. s. v Dlouhé Vsi. Děkujeme...

Reportáž z Dlouhé Vsi je online!

26. září jsme společně slavnostně otevřeli novou posklizňovou linku ZEA Rychnovsko a. s. v Dlouhé Vsi. Děkujeme...

VÝSLEDKY SOUTĚŽE

Děkujeme všem, kteří se zapojili do naší letní soutěže s PAWLICA a AGE! ☀️

Správná odpověď byla 7 zastávek Polních dní 2025 ...

VÝSLEDKY SOUTĚŽE

Děkujeme všem, kteří se zapojili do naší letní soutěže s PAWLICA a AGE! ☀️

Správná odpověď byla 7 zastávek Polních dní 2025 ...

PALWICA s.r.o. na Krajském vinobraní a dožínkách na Kačině 2025

Naše společnost měla tu čest být partnerem letošního 14. ročníku Krajského...

PALWICA s.r.o. na Krajském vinobraní a dožínkách na Kačině 2025

Naše společnost měla tu čest být partnerem letošního 14. ročníku Krajského...

This website is using cookies

The company PAWLICA s.r.o. It informs you that these pages use cookies. More detailed information about cookies and the processing of personal data can be found in Declaration on privacy protection and the use of so-called cookies. We hereby ask for your consent to the use of these cookies.